As a quality-oriented enterprise, E G never compromised on quality!

♦Early control

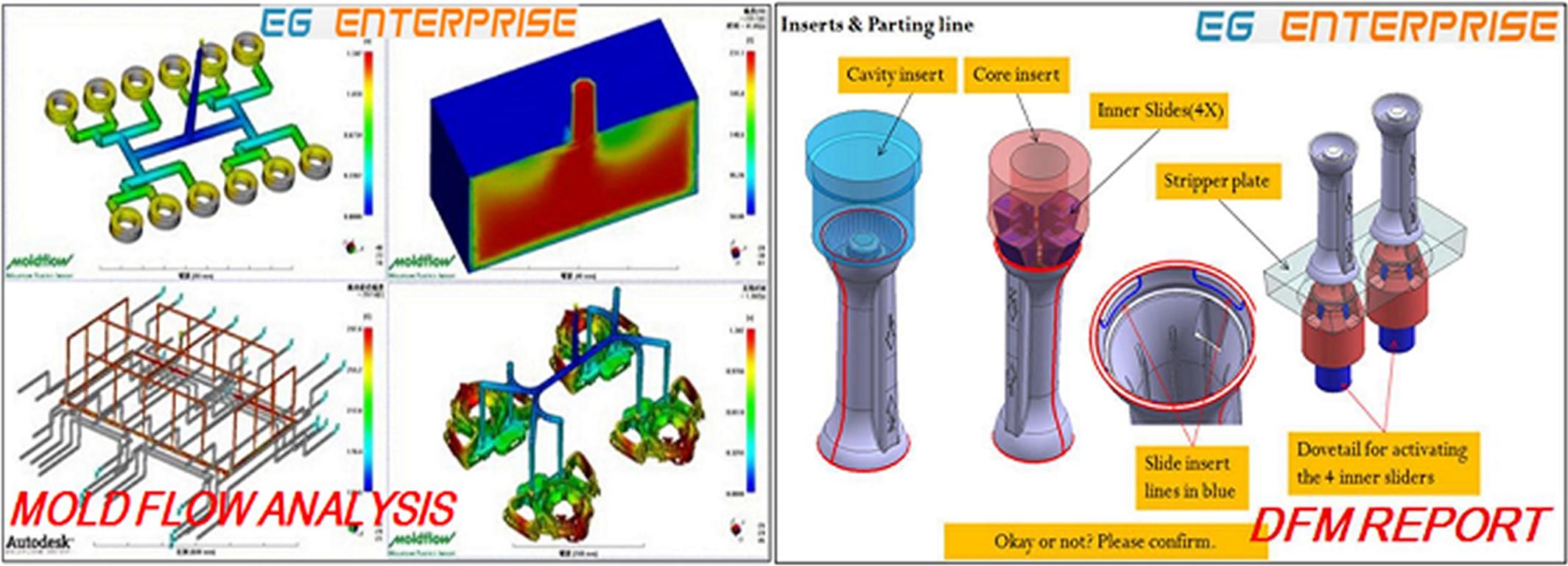

As soon as we receive P.O, our experienced engineers will take over the new project and contact with customer to get all information confirmed. Generally, DFM Report, Moldflow Report and Part Analysis Report will be submitted to customer for further review and approval.

♦Mold design review

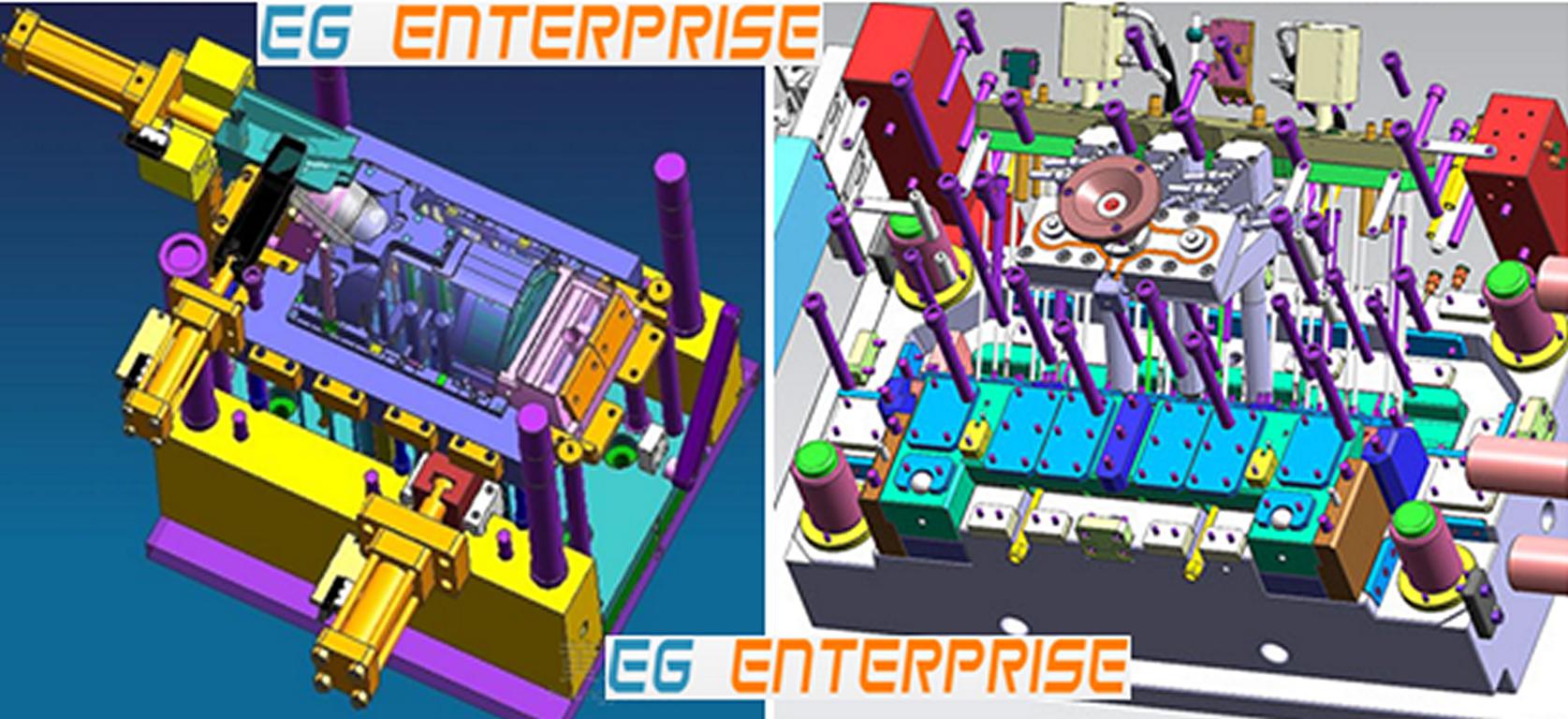

1-All molds to be designed according to all information that confirmed by customer.

2-A mold design review meeting will be organized, to have all relevant people together review the reasonability of mold structure and ensure all mold details match customer's facility.

3-The Updated mold design will be submitted to customer for review and approval.

♦ Fabrication process control

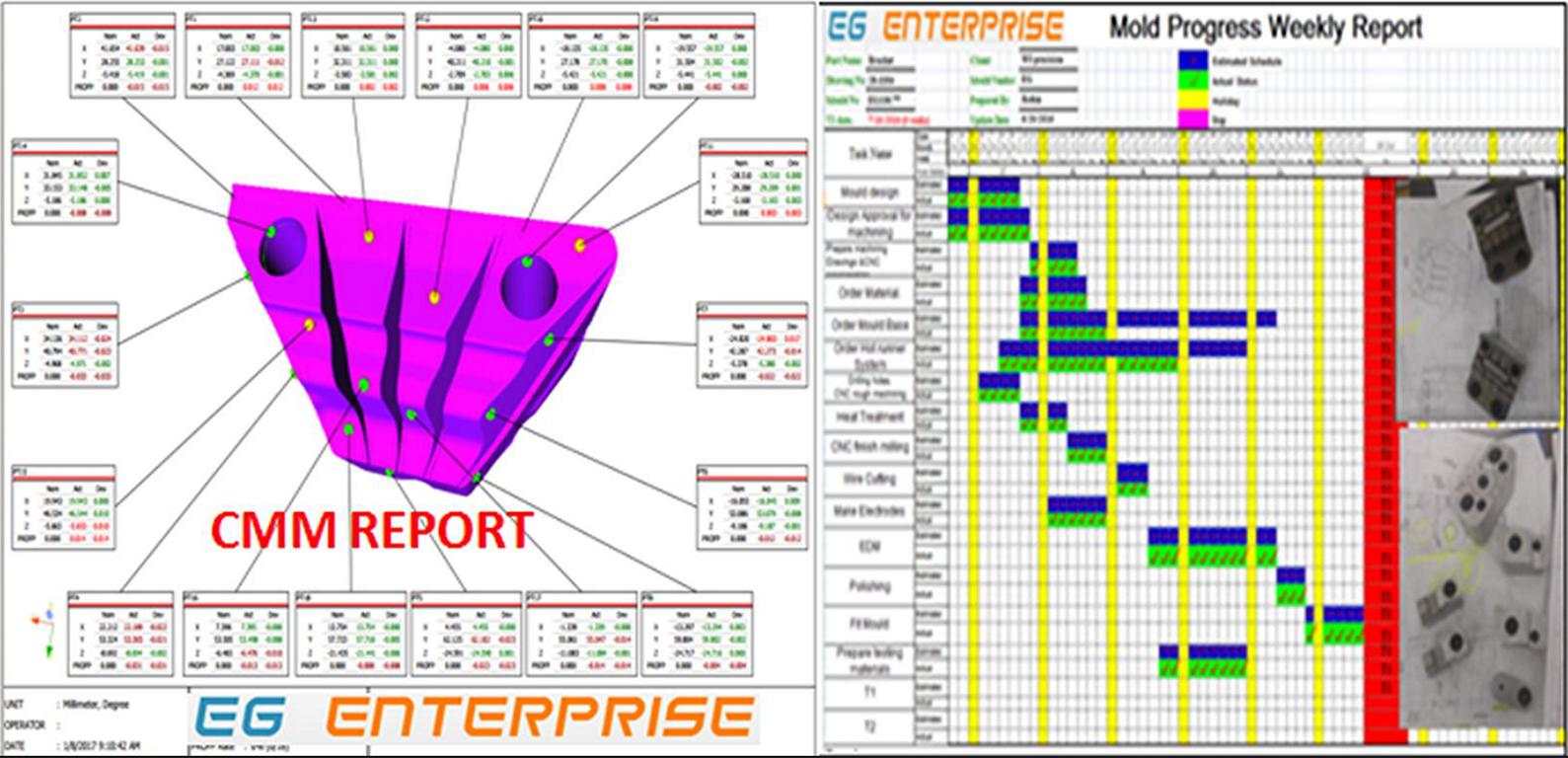

1-Make a detailed production schedule and work out a perfect machining process.

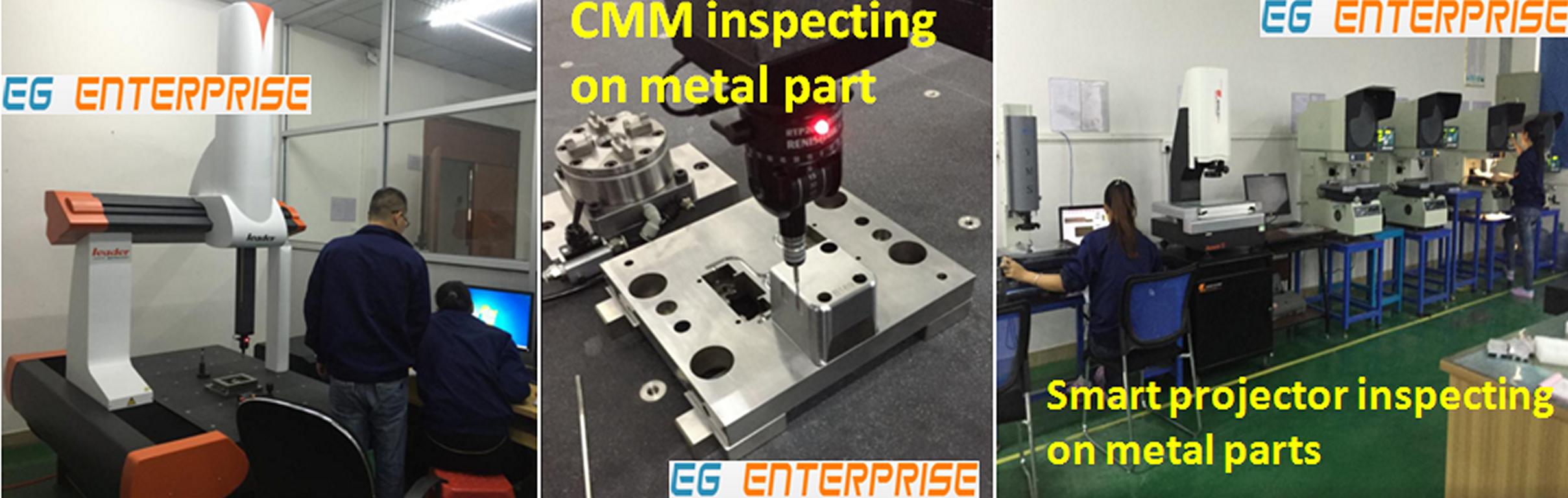

2-Inspect all parts at each process step strictly. We never allow any NG parts pass to next stage.

3-Project Engineer checks progress regularly and submits weekly process report to customer to ensure all goes well.

♦Mold trial qualifying

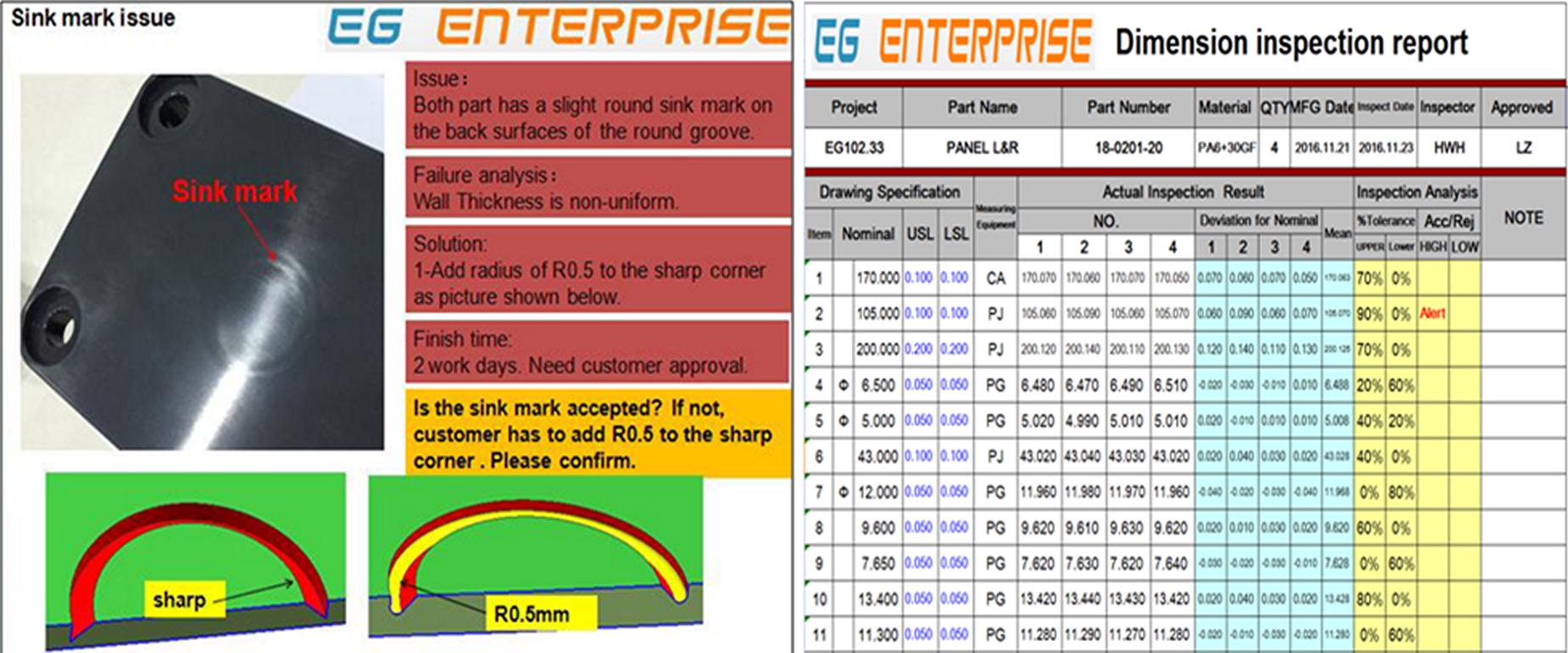

1-Apply Scientific Test Process to qualify mold performance and detect all issues at T1.

2-Check all dimensions on T1 samples according to the 2D part drawings.

3-Submit a detailed Trial Report and a Sample Dimensional Report to customer.

4-Send samples to customer for review and test.

5-Amend all issues according to customer's feedback.

♦Mold packing

1-Qualify the mold by sampling for at least 1 hour without any issue.

2-Check all details of mold to make sure they conform to customer requirements.

3-Clean the mold and components then pack them up by PE film and load them into a firm crate.

High lights,

Dongguan Electronic Devices Enclosure Injection Mold

China Electronic Devices Enclosure Injection Mold

Shenzhen Electronic Devices Enclosure Injection Mold

Electronic Devices Enclosures Machining